Cryotech Cleaning™ Trade marketed by Premier carbonic pvt ltd for Dry ice-cleaning is a form of abrasive blasting, where dry ice, the solid form of carbon dioxide, is accelerated in a pressurized air stream and directed at a surface in order to clean it. The method is similar to other forms of abrasive blasting such as sand blasting, plastic bead blasting, or soda blasting but substitutes dry ice as the blasting medium.The frigid temperature of the dry ice -109.3°F or -78.5°C “blasting” against the material to be removed, causes it to shrink and lose adhesion from its sub surface.

Process Description

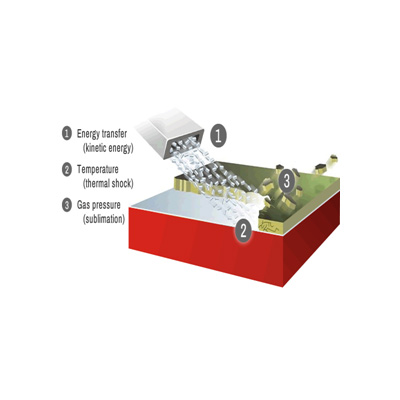

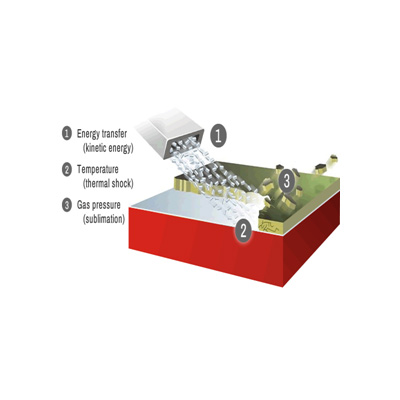

Pellet Kinetic Energy

Dry ice pellets are propelled out of the blasting gun at a very high speed. Upon impact with the surface, the energy transfer knocks off the contaminant without abrasion. This is the primary means of contaminant removal.

Thermal Shock Effect

The cold temperature of the dry ice pellets (-79 C) hitting the contaminant creates a micro-thermal shock between the surface contaminant and the substrate. Subsequent cracking and delaminating of the contaminant furthers the elimination process.

Thermal – Kinetic Effect

In the final phase of the process, the pellet expands on impact. As the pellet warms, it converts to a harmless gas, which expands rapidly beneath the contaminant surface. This forces the contaminant off from underneath. The contaminant is then relocated, typically falling to the ground. Since the CO2 sublimates instantly, only the contaminant is left for disposal.

Uses

Dry ice cleaning are very widely used in all the industries and have substituted the traditional cleaning methods in the Indian market.

| Electrical | Industrial | Food |

|---|---|---|

|

Electronic/electrical control panels |

Molding Equipment |

Ovens |

|

Cable trays, Motors/Stators |

Butt Welders |

Floors |

|

Armatures/Coils/Windings |

Process Equipment |

Walls |

|

Generators |

Piping |

Processing Equipment |

|

Transformers |

Tanks |

Conveyors |

|

Robotic Equipment |

Oil Field Equipment |

Bake-Off trays |

|

Turbines |

Boiler Tubes |

Packaging Areas and Equipment |

Benefits

- a non-abrasive, nonflammable and nonconductive cleaning method

- environmentally-friendly and contains no secondary contaminants such as solvents or grit media

- safe, clean and approved for use in the food industry

- less cleaning cycles, reduced downtime for cleaning

- cleaning can be done at the same place where the equipment is present

- can be used without damaging active electrical or mechanical parts or creating fire hazards

- can be used to remove production residues, release agents, contaminants, paints, oils and biofilms

- can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling

- can be used for many general cleaning applications

Comparisons

COMPARISIONS WITH TRADITIONAL METHODS:

| Cleaning Method | Waste disposal | ElectricallyConductive | Toxic | Abrasive | Effectiveness |

|---|---|---|---|---|---|

| Dry Ice | No | No | No | No | Excellent |

| Water | Yes | Yes | Yes | No | Average |

| Steam | No | Yes | No | No | Poor |

| Solvent/Chemicals | Yes | NA | Yes | No | Very poor |

| Soda | Yes | No | NA | Yes | Good |

| Sand | Yes | No | Yes | Yes | Good |